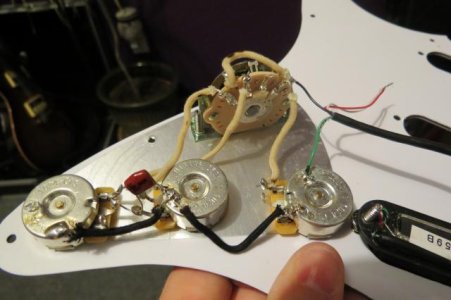

Re: First attempt wiring. How does it look?

LOVERSMOON...

First of all, ignore just about everything in this following post!

Looks pretty good. You might stand to add just a touch more solder when making some of those connections. If it's blobbing up or rolling off, tilt the whole piece to make sure it flows where you need it to go. It looks like your iron is hot enough - the solder looks nice and shiny so I wouldn't expect you have any cold joints.

Are you using single-strand or multi-stranded wire there? Multi-strand will flex more easily without stressing joints, and may hold up better over time. You may also be able to get away with using a thinner gauge wire, but it's hard to tell from the pictures what you have there.

It also looks like you could consider investing in a wire stripper. It will cut the ends of the insulation more neatly and can prevent the insulation from peeling back, especially when you are soldering and the wire heats up. It will also help you to avoid cutting or nicking the wire when you strip the ends. The multi-action clamp-and-strip kind (pictured on the left) is great, but even an inexpensive cutter/stripper (on the right) will help you out a lot.

View attachment 35291 View attachment 35290

Nice project. Have fun, and don't burn your fingertips!

A little helpful criticism, not trying to be mean, I just want to help you do better.

You certainly DON'T need more solder. Your solder joints on the backs of the pots are very bad. They are DEFINITELY

cold joints. Here's what that means: the solder itself got hot enough to melt and is nice and shiney, but the pots did not get hot. See how the solder blobs up into a ball. That is because the soldering iron did not contact the pot well enough to heat it up. When the pot back is hot enough the solder will flow like water, thin and smooth (not blobbed up in a ball). There are two things that will fascillitate this: HEAT (watts), and TIME. If you have a low wattage iron (less than 40 watts=low heat) you need to keep it in contact with the pot for a longer period of time to heat it up enough for the solder to melt and flow. Unfortunately, this allows the heat to diffuse throughout the pot and can also damage the pot (or switch). If you are using a high wattage iron (at least 40 watts) it will heat up a small area on the pot hot enough to get the solder to flow, in less time...before that heat disperses throughout the pot causing damage. Rule of thumb..."

HIGH HEAT, SHORT AND SWEET". Also, ALWAYS heat the metal (back of pot, lugs, wire) that you want the solder to flow to

not the solder. When the metal is hot enough, it will melt the solder and it will flow like water. When the solder is hot but not the metal, it will ball up on top of the metal (like it is on the backs of your pots). This is what is refered to as a :cold joint". Another rule of thumb..."

MEAT FOLLOWS HEAT" (meaning that the solder will flow toward the sourse of the heat, or the hottest area).

The wire you are using is great. It is vintage cloth covered multistranded wire. Can't get much better than that. For wiring a Strat pickguard, it is perfectly fine to use solid wire instead of stranded wire if you want, since the guard holds everything rigid anyway. In fact solid wire actually works great in that application. The guage of wire you are using is perfect. No need to go thinner, although it won't hurt anything to go thinner (as low as 24 guage is fine, 18-22 is ideal).

As far as wire strippers are concerned. They work great!!.......on plastic coated/insulated wire. Not so great on vintage cloth covered wire. If you intend on continuing to use that wire, save your money on the stripper. Just cut the wire and "push back" the cloth covering. (Incidently, that is why this type of wire is sometimes refered to as "pushback" wire).

Insulating the wires on the cap is a good idea to prevent any possible shorts.

Finally.....your wiring job looks nice and neat. You have a good eye for detail and I'm sure that when you improve your soldering technique you will be doing some superb work that will be enveyed by many...and you'll actually enjoy it more since you will have no need to keep redoing poor solder joints. Do it right the first time and eliminate the second and third times.