cooldonkey

New member

So hey guys, super noob question: I have a set of bucks that I've thrown/exchanged in a couple of guitars cause I really like they way sound. (Sentient & Pegasus)

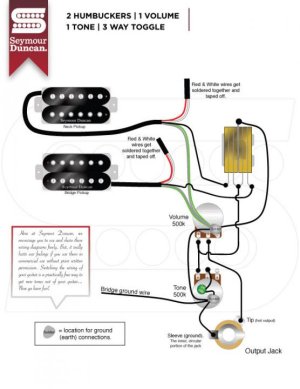

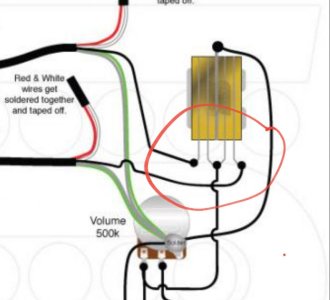

I thought I had installed them without push pulls/splitting coils before. (I could be wrong it's been a while) I've installed them in a new guitar without push pulls, and I thought I had found the right diagram, but both the pickups are always on and making a lot of noise regardless where the 3 way selector is at. (2 Humbuckers, 1 Vol, 1 Tone, 3 way toggle. Not push pulls pots.) Could someone direct me to the correct diagram, or just tell me I'm all f'__ed up. lol.. Thanks!

I thought I had installed them without push pulls/splitting coils before. (I could be wrong it's been a while) I've installed them in a new guitar without push pulls, and I thought I had found the right diagram, but both the pickups are always on and making a lot of noise regardless where the 3 way selector is at. (2 Humbuckers, 1 Vol, 1 Tone, 3 way toggle. Not push pulls pots.) Could someone direct me to the correct diagram, or just tell me I'm all f'__ed up. lol.. Thanks!