You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

So you think you can solder....

- Thread starter Lewguitar

- Start date

Lewguitar

New member

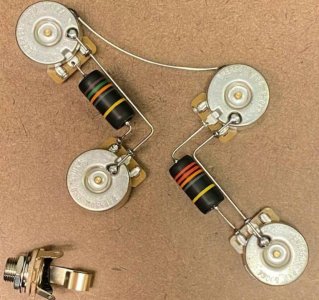

I certainly can appreciate a neat & tidy job. I wonder how much he is charging people for this.

$90. Emerson Custom Wired Kit. Sweetwater has them.

PFDarkside

of the Forum

Non-insulated, interesting. How will it look once someone globs solder all over to ground the braided shield on the Vintage accurate PAFs the eventual buyer uses.

Dave Locher

New member

Nice!

I never would have thought of this but on another forum a dude mentioned that using a solid wire ground like that keeps the pots from rotating if they come loose in the guitar.

I never would have thought of this but on another forum a dude mentioned that using a solid wire ground like that keeps the pots from rotating if they come loose in the guitar.

Lewguitar

New member

just measure bare wire length for each piece, take the flat part of a needlenose pliers (or similar flat edge) and bend wire 90 degrees (or whatever) accordingly... position, then solder.

helping hands may... help as well.

Yeah. And all you need is some paint, paint brushes and a canvas to paint like Norman Rockwell.

I can do a pretty good job but that guy's soldering is like artwork!

Last edited:

Ascension

Well-known member

Nice!

I never would have thought of this but on another forum a dude mentioned that using a solid wire ground like that keeps the pots from rotating if they come loose in the guitar.

Carvin Kiesel has used a sold Ground on their guitars for years. I can do that kind of work if I take my time it just takes a steady hand and patience.

Condemnedsoul

Active member

That is what my soldering looked like while I was in the military and doing component repair work, however, that was many aeons ago.

The finished assembly .....

Wires nicely bent - look preformed

solder joints are small and smooth

Layout - uncluttered and efficient

Looks like it was made on an assembly line or by someone that had the good tools and plenty of time.

Regardless of who, what, when, where, nicely done.

The finished assembly .....

Wires nicely bent - look preformed

solder joints are small and smooth

Layout - uncluttered and efficient

Looks like it was made on an assembly line or by someone that had the good tools and plenty of time.

Regardless of who, what, when, where, nicely done.

Artie

Peaveyologist

Nice!

I never would have thought of this but on another forum a dude mentioned that using a solid wire ground like that keeps the pots from rotating if they come loose in the guitar.

I do that too. I use a 18 AWG solid intercom wire. Big enough to be strong and easy to work with, but not so large that it acts as a big heatsink when soldering.

As for those pre-wired pots, they look neat and tidy, but they also don't look like they're spaced properly for an LP. That would mean you'd have to bend that pretty work to get to fit in the guitar. I could be wrong about that, but it just doesn't look right. Nice soldering, though.

Last edited:

Lewguitar

New member

I do that too. I use a 20 AWG solid intercom wire. Big enough to be strong and easy to work with, but not so large that it acts as a big heatsink when soldering.

As for those prewired pots, they look neat and tidy, but they also don't look like they're spaced properly for an LP. That would mean you'd have to bend that pretty work to get to fit in the guitar. I could be wrong about that, but it just doesn't look right. Nice soldering, though.

That's for a PRS. A McCarty maybe?

Lewguitar

New member

90 bucks for about 15 in parts. I would make sure the soldering was perfect too.

No crime in making a profit at what you love doing and have learned to do better than just about anyone else.

I'll bet an Antiquity humbucker has about the same mark up if all you're going to do is compare the selling price to the cost of parts.

No crime in making a profit at what you love doing and have learned to do better than just about anyone else.

I'll bet an Antiquity humbucker has about the same mark up if all you're going to do is compare the selling price to the cost of parts.

No crime. I was just saying that I bet most of the people here could make it that clean if they really needed/wanted to. Give me a nice tip and an hour, I bet I could come close (after a handful of screwups).

Lewguitar

New member

No crime. I was just saying that I bet most of the people here could make it that clean if they really needed/wanted to. Give me a nice tip and an hour, I bet I could come close (after a handful of screwups).

"After a handful of screwups." Hey...I resemble that remark! lol!

Similar threads

- Replies

- 14

- Views

- 433

- Replies

- 33

- Views

- 714