Re: Solder not sticking to the Pot, Help!

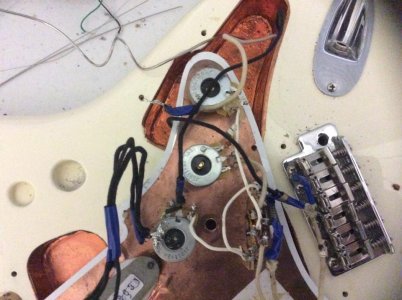

Soldering was my chore when I was a kid; Dad was a ham radio operator/restorer, so I did simple stuff for him for pocket money. The quick trick I found was to use a few simple steps. First, check your soldering tip and make sure that it's not corroded (rusty or greenish deposits, pock marks, gouges or anything like that) and verify the wattage of your iron. If your tip is damaged, no worries. Weller tips are about 7 bucks for a 3 pack at the hardware store and super easy to install. Second, like the other guys said, clean and scuff your soldering surface. Third, "tin" the tip, the wire. This means melting a very small amount of solder onto the tip by touching the solder with the tip of the iron, taking that solder and applying just a little to the last bit of the wire that you're going to attach to the pot. Now lay the iron on your scuffed pot area with the beveled part of the end making contact and hold it there for about 4 seconds for a 60w iron (it is possible to damage a pot by overheating). You'll know it's hot enough by touching the solder to the pot as close to the iron as you can without touching the iron and melting solder to the surface of the pot. When you've applied solder to the joint, you'll need to remove the iron but be sure to keep the wire held in place until your joint cools (3-4 seconds; blow on it), i.e. don't use the iron to hold the wire down because it'll move when you pick up the iron and you'll be back to square one, only with a mess. That's pretty much all the places where you can make a mistake in this type of soldering if you're new to it. Probably a bit lengthy, but it's equally easy to do right or screw up.... Good luck and remember to plan your moves out, draw your circuits and take your time. Building circuits is actually pretty fun.