Hi, got an old (has Schaller made in w.germany) custom build guitar; dont know who built it or when...

The trussrod was normally adjusted by me, tightening with clockwork motion.

Then the neck bend more backwards, as if string gauge had increased.

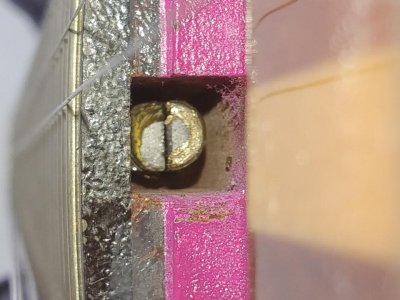

If i try counter-clockwise, the nut of the truss-rod comes off...

Is this faulty install?

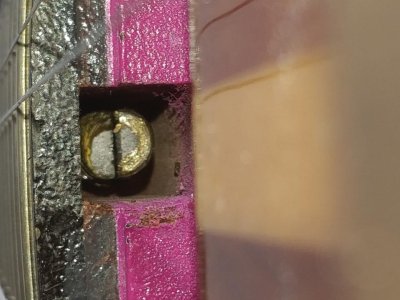

(The truss rod nut is underneath the neck pickup, pulling it wont work ;-/ )

The trussrod was normally adjusted by me, tightening with clockwork motion.

Then the neck bend more backwards, as if string gauge had increased.

If i try counter-clockwise, the nut of the truss-rod comes off...

Is this faulty install?

(The truss rod nut is underneath the neck pickup, pulling it wont work ;-/ )