ThreeChordWonder

New member

My rattle can skills are abysmal so the plan for the 335 kit I received yesterday is either natural mahogany with wipe on poly over or cherry red then wipe on poly over.

Can anyone recommend a wood stain that will give me that Gibson cherry red look?

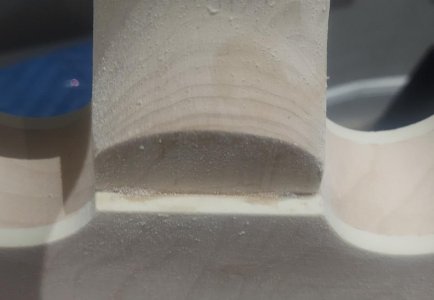

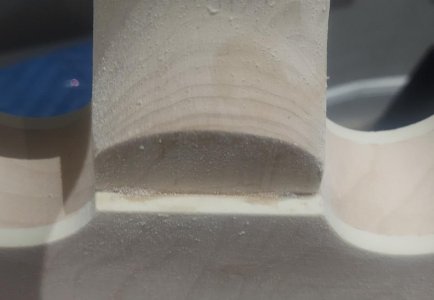

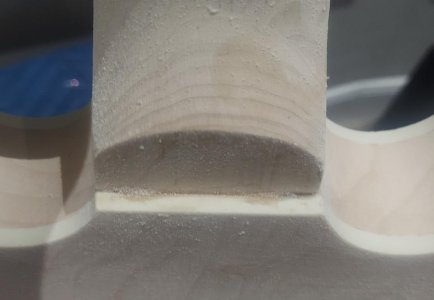

Also, can anyone suggest a wood filler that will go into the gaps in the neck joint, sand to a fine feathered edge and take stain?

I glued the neck in pretty much dead straight but the joint isn't exactly air tight down the sides. If I have to use Bondo I will probably end up staining the edge of the body black to mask it, which I don't want to do if I can avoid it.

Pictures tomorrow.

Thanks in advance.

Can anyone recommend a wood stain that will give me that Gibson cherry red look?

Also, can anyone suggest a wood filler that will go into the gaps in the neck joint, sand to a fine feathered edge and take stain?

I glued the neck in pretty much dead straight but the joint isn't exactly air tight down the sides. If I have to use Bondo I will probably end up staining the edge of the body black to mask it, which I don't want to do if I can avoid it.

Pictures tomorrow.

Thanks in advance.