Dr. Vegetable

New member

Re: First attempt wiring. How does it look?

Good points, Doc!

My comments about more solder / shiny joints were more meant about the connections on the switch/pot terminals, not the ground connections on the pot cans which had already been called out as unnecessary and recommended to be removed by others. I think the soldering work in general looks very good for a first-time job. I could have been more clear in my post.

The wire gauge is probably just fine, and that does indeed look like multi-strand wire after all. But it appears to be several gauges heavier than the leads from the pickups. As I am sure you know, heavy gauge can be more difficult to work with, requires more heat to solder properly, and will not always fit through the terminals especially when joined to another wire. It is also not as flexible as thinner wire, so can make re-assembly more difficult than it has to be. Using the correct size and type of wire for the job is more likely to lead to satisfactory results and a more durable build.

FWIW, I still would not recommend solid-core wire for a job like this, as it is more susceptible to fatigue. For example, the white wire jumpering the pickup selector switch will get crushed flat when the pickguard is re-attached to the guitar, and this could stress the solder connections at both ends if that wire were not flexible enough. Nothing sucks more than having a working circuit that breaks when you screw everything back together. Solid core wire is not generally used in soldered applications, just as stranded wire is not ideal for making screw-terminal connections, and I have never seen factory or craftsman guitar wiring that was done with solid core. YMMV.

The wire strippers I suggested will not work on cloth insulation, so my advice was misguided in this context. They are an important tool to have if you are doing much electrical work, and still worth adding to the toolbox when a decent pair of strippers can be had for about $5.

The ground connection on the leftmost pot looks much better than before. Notice how the solder lays in a smooth mound rather than in a rounded blob. That means you did have enough heat and a good solder flow when you made that connection. The other two ground connections look sketchy, though. Try to get them to look like the first one and you should be in good shape.

I apologize if any of my advice was misleading. I'll defer to GuitarDoc for any further instruction in this area, as he is clearly quite experienced with this kind of work and most generous with his advice. I hope you are learning a lot and getting good practice with the iron. Keep at it and enjoy the toxic fumes!

LOVERSMOON...

First of all, ignore just about everything in this following post!

You certainly DON'T need more solder. Your solder joints on the backs of the pots are very bad. They are DEFINITELY cold joints.

...

The wire you are using is great. It is vintage cloth covered multistranded wire. Can't get much better than that. For wiring a Strat pickguard, it is perfectly fine to use solid wire instead of stranded wire if you want, since the guard holds everything rigid anyway. In fact solid wire actually works great in that application. The guage of wire you are using is perfect. No need to go thinner, although it won't hurt anything to go thinner (as low as 24 guage is fine, 18-22 is ideal).

As far as wire strippers are concerned. They work great!!.......on plastic coated/insulated wire. Not so great on vintage cloth covered wire. If you intend on continuing to use that wire, save your money on the stripper. Just cut the wire and "push back" the cloth covering. (Incidently, that is why this type of wire is sometimes refered to as "pushback" wire).

...

Good points, Doc!

My comments about more solder / shiny joints were more meant about the connections on the switch/pot terminals, not the ground connections on the pot cans which had already been called out as unnecessary and recommended to be removed by others. I think the soldering work in general looks very good for a first-time job. I could have been more clear in my post.

The wire gauge is probably just fine, and that does indeed look like multi-strand wire after all. But it appears to be several gauges heavier than the leads from the pickups. As I am sure you know, heavy gauge can be more difficult to work with, requires more heat to solder properly, and will not always fit through the terminals especially when joined to another wire. It is also not as flexible as thinner wire, so can make re-assembly more difficult than it has to be. Using the correct size and type of wire for the job is more likely to lead to satisfactory results and a more durable build.

FWIW, I still would not recommend solid-core wire for a job like this, as it is more susceptible to fatigue. For example, the white wire jumpering the pickup selector switch will get crushed flat when the pickguard is re-attached to the guitar, and this could stress the solder connections at both ends if that wire were not flexible enough. Nothing sucks more than having a working circuit that breaks when you screw everything back together. Solid core wire is not generally used in soldered applications, just as stranded wire is not ideal for making screw-terminal connections, and I have never seen factory or craftsman guitar wiring that was done with solid core. YMMV.

The wire strippers I suggested will not work on cloth insulation, so my advice was misguided in this context. They are an important tool to have if you are doing much electrical work, and still worth adding to the toolbox when a decent pair of strippers can be had for about $5.

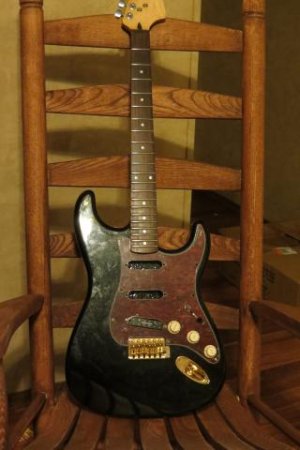

View attachment 35400

well second attempt to try and clean up the first. I cant tell if its better or worse. did get the switch so it will turn into all five slots now.

The ground connection on the leftmost pot looks much better than before. Notice how the solder lays in a smooth mound rather than in a rounded blob. That means you did have enough heat and a good solder flow when you made that connection. The other two ground connections look sketchy, though. Try to get them to look like the first one and you should be in good shape.

I apologize if any of my advice was misleading. I'll defer to GuitarDoc for any further instruction in this area, as he is clearly quite experienced with this kind of work and most generous with his advice. I hope you are learning a lot and getting good practice with the iron. Keep at it and enjoy the toxic fumes!