I changed out the foam on my Warmoth to SD pickup foam from their packaging. While looking for it, I found 2 pickups I didn't realize I had, so win/win. I did try springs, but they didn't work as well. I still needed foam underneath or the pickup would tilt. I then realized it is stable and not tilting with the pickup foam itself.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

There is no good way to direct wood-mount pickups

- Thread starter Mincer

- Start date

Rex_Rocker

Well-known member

I don't think the pickups should sit parallel to the guitar top, but rather, parallel to the strings. Which then, proves another challenge, either with pickup rings or without.

I changed out the foam on my Warmoth to SD pickup foam from their packaging. While looking for it, I found 2 pickups I didn't realize I had, so win/win. I did try springs, but they didn't work as well. I still needed foam underneath or the pickup would tilt. I then realized it is stable and not tilting with the pickup foam itself.

what pups?

what pups?

Alnico II Pro/Custom Custom. I had them in another guitar I sold, so I put that guitar back to stock and pilfered the pickups.

NotDemanic

Active member

Couldn't you get an insert that would fit a standard pickup screw and then just put springs underneath the pickup ?

Chistopher

malapterurus electricus tonewood instigator

Couldn't you get an insert that would fit a standard pickup screw and then just put springs underneath the pickup ?

Thats what EVH does. All of their wood mount guitars that I've seen have 2 screws per pickup leg and some springs and foam underneath them. Gives you maybe 1/8" of height adjustment

Couldn't you get an insert that would fit a standard pickup screw and then just put springs underneath the pickup ?

Well, it works better with an insert and a screw that passes right through a normal pickup baseplate hole, not one that screws through it. Then you can use springs, although sometimes the pickup tilts one way or the other. I found it easier to not use springs, and just use pickup foam underneath.

Spaghetti Bolo

New member

I use the skinny screws too on both buckers and singles to avoid altering them.

First direct mount I ever did was completely non adjustable; Tele bridge pickup screwed flat down onto a glued in mahogany insert pre-shaped for the correct height, with reliefs carved into it for the pickup leads.

Last one I did was adding a middle single coil to a HH Jackson. I went with a shallow rout, skinny wood screws and very short lengths of surgical tubing that allow for a little adjustment. That's the current go-to for direct mounting.

All pickups need to use 3 screw mounting imo. Leo got it right with the Tele bridge pickup, went backwards with the Strat, then overcompensated with the 4 screw Jazzmaster/Jbass. Yamaha and Fender have dabbled in 3 screw humbuckers, I really wish it became the standard. I'm slowly converting all my humbucker guitars to 3 screw.

Finally, I used to hate the aesthetics of pickups rings but have softened on them because function>form. I also don't believe (anymore) that tone is improved by direct-mounting; handling noise is definitely exacerbated though.

First direct mount I ever did was completely non adjustable; Tele bridge pickup screwed flat down onto a glued in mahogany insert pre-shaped for the correct height, with reliefs carved into it for the pickup leads.

Last one I did was adding a middle single coil to a HH Jackson. I went with a shallow rout, skinny wood screws and very short lengths of surgical tubing that allow for a little adjustment. That's the current go-to for direct mounting.

All pickups need to use 3 screw mounting imo. Leo got it right with the Tele bridge pickup, went backwards with the Strat, then overcompensated with the 4 screw Jazzmaster/Jbass. Yamaha and Fender have dabbled in 3 screw humbuckers, I really wish it became the standard. I'm slowly converting all my humbucker guitars to 3 screw.

Finally, I used to hate the aesthetics of pickups rings but have softened on them because function>form. I also don't believe (anymore) that tone is improved by direct-mounting; handling noise is definitely exacerbated though.

Yeah, I don't hear a tone difference- and after the initial frustration of putting inserts in, I love the look. The mounting tabs look a little unfinished unless you have the baseplates the new Rails pickups use.

But I am sure some engineers could figure out a way to do it better, without completely re-designing the system and without losing the ability to use rings.

But I am sure some engineers could figure out a way to do it better, without completely re-designing the system and without losing the ability to use rings.

NotDemanic

Active member

I'm surprised that no one has just 3D printed one.

Ascension

Well-known member

Several here have talked about trying to use the foam from the box on a Duncan pickup. Does not work well at all, it's too soft. What Washburn used for the Grover era guitars that direct mounted was much denser. The only thing I have found that is close is the foam used for exercise mats.

They cut it to fit the baseplate of the pickup then set the pickup down on it and pushed the pole pieces down into the foam to leave an imprint then drilled it to let the pole pieces slide into the hole, so the foam sat flat against the bottom plate of the pickup. They then used the inserts and machine screws with rubber tubing to mount them. Elegant simple and the absolute best direct mount system I have ever seen used for any guitar.

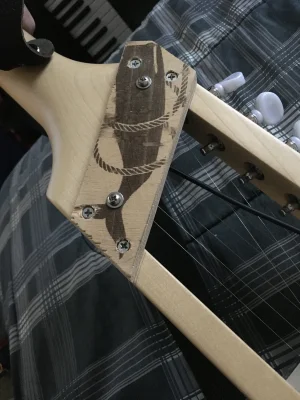

My 95 MG 102. The stock bridge pickup on this one was a Pearly Gates, but was a JB on my other swamp as body MG 100. I prefer the JB in Swamp ash, so I swapped in the JB so no black back and the logo, otherwise she is stock.

They cut it to fit the baseplate of the pickup then set the pickup down on it and pushed the pole pieces down into the foam to leave an imprint then drilled it to let the pole pieces slide into the hole, so the foam sat flat against the bottom plate of the pickup. They then used the inserts and machine screws with rubber tubing to mount them. Elegant simple and the absolute best direct mount system I have ever seen used for any guitar.

My 95 MG 102. The stock bridge pickup on this one was a Pearly Gates, but was a JB on my other swamp as body MG 100. I prefer the JB in Swamp ash, so I swapped in the JB so no black back and the logo, otherwise she is stock.

Attachments

Chistopher

malapterurus electricus tonewood instigator

You have to use a lot more pickup box foam than you think you need for it to work. I did that for years- now, it is just springs and threaded inserts, but I still wish there was a better way (and better looking) way to do this. Maybe from the back?

Gibson tried rear adjustable wood mount pickups. The problem is that people who love or hate Gibson refuse to accept anything they do, so it was never seen again.

Ascension

Well-known member

You can stuff more box foam in there, but it still doesn't work well. It's using the denser foam that makes the difference. It's not just about the look it sounds different. Dampens the vibration to the pickup from the body and lets the pickup catch the tone differently from the actual strings. No one else I have seen has done it like they did while Grover was there. Had to be a little labor-intensive though as each foam block was hand cut and fitted.You have to use a lot more pickup box foam than you think you need for it to work. I did that for years- now, it is just springs and threaded inserts, but I still wish there was a better way (and better looking) way to do this. Maybe from the back?

I think the denser foam used in the current production Jackson & Charvel works very well. Also, Ibanez use short & wide springs, they have this 3-4mm thick foam sitting in the pickup cavity with a round hole cut to size for the spring to sit in there snug when you install the pickup.

What gets me every time with regard to direct mounting pickups is when I see pickups for sale with the screw holes widened because they were "direct mounted". Don't be a dumba$s and butcher the pickup backplate for a larger screw, how about you use the proper size screw in the first place? If they can do it in the factory, so can you?

What gets me every time with regard to direct mounting pickups is when I see pickups for sale with the screw holes widened because they were "direct mounted". Don't be a dumba$s and butcher the pickup backplate for a larger screw, how about you use the proper size screw in the first place? If they can do it in the factory, so can you?

Last edited:

Similar threads

- Replies

- 10

- Views

- 578

- Replies

- 30

- Views

- 1K

- Replies

- 7

- Views

- 386