blueman335

Mojo's Minions

Re: Easy pickup changing solution

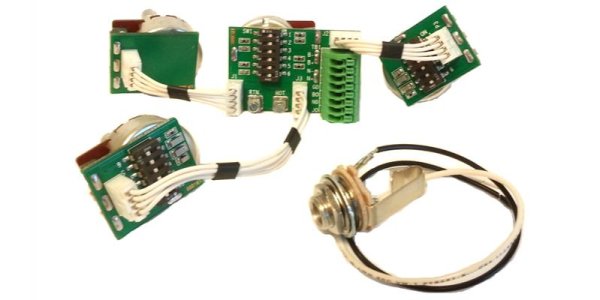

Not a strawman. As I said, I have guitars where I couldn't even get a 4-lead wires thru the wire channel in the guitar body. Connectors of any kind would be impossible to get thru there. Guitar makers aren't building their produts with the thought that their customers will be stuffing all kinds of things thru those channels. They build according to their needs, not what aftermarket products might be used.

- Blueman, a connector system does not need to be substantially bigger than the current wire. This is merely a strawman. You can make a system that fits in narrow channels. I did with a random idea and a few minutes walking around an electronics store. The R &D? $10 to buy supplies. I use a connector system, and the truth is, the opposition to a quick connect is really presenting nothing that presents a substantive issue, except tradition.

Not a strawman. As I said, I have guitars where I couldn't even get a 4-lead wires thru the wire channel in the guitar body. Connectors of any kind would be impossible to get thru there. Guitar makers aren't building their produts with the thought that their customers will be stuffing all kinds of things thru those channels. They build according to their needs, not what aftermarket products might be used.