You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wiring Diag Help Needed

- Thread starter THRobinson

- Start date

THRobinson

New member

THRobinson

New member

GuitarDoc these ones? On sale and a 3pk as luck would have it

SALECOM 3X DPDT 6 Pin 3 Position ON/ON/ON Guitar Mini Toggle Switch Car/Boat Switches https://a.co/d/bM4zymn

The 2way I have though are dpdt not spst... Will I need to switch that for a new one as well?

https://nextgenguitars.ca/products/mini-switch-standard-dpdt-on-on.html

3way selector I have is just a generic Les Paul style 3way toggle like in the diagram. Pots are Alpha a500k's for vol and tone, and an 0.047uf cap.

SALECOM 3X DPDT 6 Pin 3 Position ON/ON/ON Guitar Mini Toggle Switch Car/Boat Switches https://a.co/d/bM4zymn

The 2way I have though are dpdt not spst... Will I need to switch that for a new one as well?

https://nextgenguitars.ca/products/mini-switch-standard-dpdt-on-on.html

3way selector I have is just a generic Les Paul style 3way toggle like in the diagram. Pots are Alpha a500k's for vol and tone, and an 0.047uf cap.

THRobinson

New member

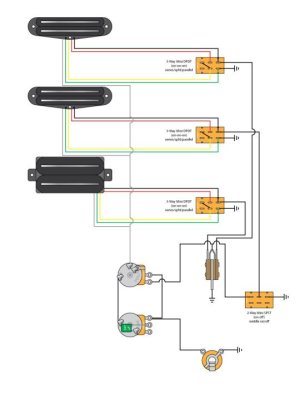

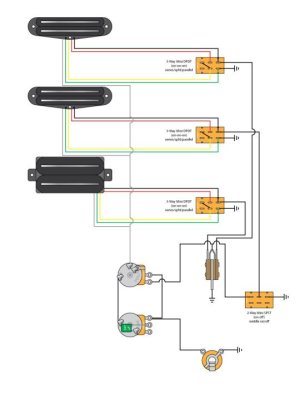

OK... How's this look?

Also, for the mini switches and grounding, can I run a buss wire from switch-to-switch soldered to the housing? or do I have to ground off that lug?

Hmm, no matter how I save the image, once uploaded here it looks like a blotchy mess. They must have some sorta compression for images.

Wiring wise, Yellow=White... just easier to see that way. The Green wire I have paired with the bare grounding wire.

Also, for the mini switches and grounding, can I run a buss wire from switch-to-switch soldered to the housing? or do I have to ground off that lug?

Hmm, no matter how I save the image, once uploaded here it looks like a blotchy mess. They must have some sorta compression for images.

Wiring wise, Yellow=White... just easier to see that way. The Green wire I have paired with the bare grounding wire.

Last edited:

I don't think you need to run a ground wire on the mini sw. housings...could damage the sw. I have used hundreds of those and have never grounded them and have had no problems.

Do NOT run the green wire and the bare wire together!!!! (This is just a good technique to follow as a general rule. It may not be important in your wiring but it would be critical if you had a phase switch. It's just good to get used to keeping them separate.).

The bare wires are baseplate ground wires which should go directly to a ground (back of pot). The green wire is the start of a coil wind wire, and goes to the switch lug indicated, then to a ground (back of pot).

If you already have a DPDT mini on/on, there is no need to buy a SPST (or SPDT) to use as the middle pup on/off switch. The switch you have will work just fine, you'll just use 1/2 of it. Just connect it as you have in your diagram, but move the ground connection up to the lug above where you show it.

Good luck.

Do NOT run the green wire and the bare wire together!!!! (This is just a good technique to follow as a general rule. It may not be important in your wiring but it would be critical if you had a phase switch. It's just good to get used to keeping them separate.).

The bare wires are baseplate ground wires which should go directly to a ground (back of pot). The green wire is the start of a coil wind wire, and goes to the switch lug indicated, then to a ground (back of pot).

If you already have a DPDT mini on/on, there is no need to buy a SPST (or SPDT) to use as the middle pup on/off switch. The switch you have will work just fine, you'll just use 1/2 of it. Just connect it as you have in your diagram, but move the ground connection up to the lug above where you show it.

Good luck.

THRobinson

New member

I thought it would be easier to run together, basically fewer wires in the way when done. Mini switch housing wise, I wasn't sure if the ground going to the switch meant the housing was grounded as well in which case could treat them as pots, running a wire from housing-to-housing instead of the lug. Though now if the bare wire not with the green then that leaves a bit more space to solder with.

Made the changes... So if not running green/bare together, then the switch lugs for grounding, can I daisy link them together and run them to the vol pot as well? even though the bare wires are also going to the same pot? Lotta wire grounding on that one pot but, it's the closest one. Also makes you think guitars should just have a terminal block or central screw to run all grounding to.

Made the changes... So if not running green/bare together, then the switch lugs for grounding, can I daisy link them together and run them to the vol pot as well? even though the bare wires are also going to the same pot? Lotta wire grounding on that one pot but, it's the closest one. Also makes you think guitars should just have a terminal block or central screw to run all grounding to.

Your diagram looks great.

Like I said, in your wiring scheme, you could have them together. Electrically it makes no difference. But then you would have the green wire + the large bare wire + another wire that goes to ground (back of pot) all together on that tiny terminal on each mini switch. That's NOT "fewer wires in the way". You're bound to have some problems with inadvertent shorting of that mess with other lugs, or problems of overheating the switch and destroying it when soldering that much to the lug. The green wire + another (small, 22-28 gauge) insulated wire on that lug is plenty.

I wouldn't solder any wires to the housing of those mini switches, it might overheat them and destroy them. Plus, it's really not necessary. I've installed hundreds of mini switches without grounding their housings and have had no problems.

A grounding block is a good idea and there are many that do that. If done well it keeps things clean and simple and reduces the chance of shorting.

What I recommend is to pigtail the ground wires together from the 4 switches with a 5th wire to go to the 3-way selector switch ground lug and from there a wire going to the back of the Tone pot. The soldered junction of those 5 wires should be insulated either with heat shrink or electrical tape.

Likewise, you could pigtail the three unshielded pickup wires together with another wire that would go to the back of the Volume pot.

(By pigtailing wires together you have fewer wires soldered on lugs and pot backs.)

Then run an insulated wire from the ground lug of the output jack to either of the pots.

I always use insulated wire for everything, even the ground wires, and I put heatshrink on all the bare wires from the pups to insulate them. I don't want even the possibility of any shorts...it's a nightmare to find and fix that kind of a problem after the fact.

Just a note about soldering:

The higher the wattage of the soldering iron the better (at least 40 watts, but 50-100 is better). A lot of heat for a short period of time is MUCH less damaging to the components than low heat for a long period of time. Yes, either will physically work, but we also, like a doctor, want to cause no harm.

Remember, "meat follows heat", meaning heat whatever is being soldered (back of pot, switch lug, etc) and add the solder to the already heated metal letting it flow onto it like water. Don't heat the solder and add it to the metal. This can give you "cold solder joints" which can fail electrically.

You don't need globs of solder. It doesn't increase the physical strength of the bond, but can cause excessive heat to the components and even cold solder joints. Let the solder flow thin like water.

Use regular 60/40 solder. Other formulas require more heat...ok for some things but not good on delicate guitar components.

I thought it would be easier to run together, basically fewer wires in the way when done.

Like I said, in your wiring scheme, you could have them together. Electrically it makes no difference. But then you would have the green wire + the large bare wire + another wire that goes to ground (back of pot) all together on that tiny terminal on each mini switch. That's NOT "fewer wires in the way". You're bound to have some problems with inadvertent shorting of that mess with other lugs, or problems of overheating the switch and destroying it when soldering that much to the lug. The green wire + another (small, 22-28 gauge) insulated wire on that lug is plenty.

Mini switch housing wise, I wasn't sure if the ground going to the switch meant the housing was grounded as well in which case could treat them as pots, running a wire from housing-to-housing instead of the lug. Though now if the bare wire not with the green then that leaves a bit more space to solder with.

I wouldn't solder any wires to the housing of those mini switches, it might overheat them and destroy them. Plus, it's really not necessary. I've installed hundreds of mini switches without grounding their housings and have had no problems.

Made the changes... So if not running green/bare together, then the switch lugs for grounding, can I daisy link them together and run them to the vol pot as well? even though the bare wires are also going to the same pot? Lotta wire grounding on that one pot but, it's the closest one. Also makes you think guitars should just have a terminal block or central screw to run all grounding to.

A grounding block is a good idea and there are many that do that. If done well it keeps things clean and simple and reduces the chance of shorting.

What I recommend is to pigtail the ground wires together from the 4 switches with a 5th wire to go to the 3-way selector switch ground lug and from there a wire going to the back of the Tone pot. The soldered junction of those 5 wires should be insulated either with heat shrink or electrical tape.

Likewise, you could pigtail the three unshielded pickup wires together with another wire that would go to the back of the Volume pot.

(By pigtailing wires together you have fewer wires soldered on lugs and pot backs.)

Then run an insulated wire from the ground lug of the output jack to either of the pots.

I always use insulated wire for everything, even the ground wires, and I put heatshrink on all the bare wires from the pups to insulate them. I don't want even the possibility of any shorts...it's a nightmare to find and fix that kind of a problem after the fact.

Just a note about soldering:

The higher the wattage of the soldering iron the better (at least 40 watts, but 50-100 is better). A lot of heat for a short period of time is MUCH less damaging to the components than low heat for a long period of time. Yes, either will physically work, but we also, like a doctor, want to cause no harm.

Remember, "meat follows heat", meaning heat whatever is being soldered (back of pot, switch lug, etc) and add the solder to the already heated metal letting it flow onto it like water. Don't heat the solder and add it to the metal. This can give you "cold solder joints" which can fail electrically.

You don't need globs of solder. It doesn't increase the physical strength of the bond, but can cause excessive heat to the components and even cold solder joints. Let the solder flow thin like water.

Use regular 60/40 solder. Other formulas require more heat...ok for some things but not good on delicate guitar components.

THRobinson

New member

Thanks for the help... few weeks out yet for doing this since just finished sanding the old finish off and pickups still in transit but, when done I'll upload the results,.

THRobinson

New member

THRobinson

New member

Ya, I have the 2way switches and the 3way came today as well, on sale about $8CAD for a 3-pack.

But if I wanted the 2way instead, the diagram wouldn't change at all, with exception of the 2-way mini's correct? What wires would I swap around using these

https://nextgenguitars.ca/products/mini-switch-standard-dpdt-on-on.html

But if I wanted the 2way instead, the diagram wouldn't change at all, with exception of the 2-way mini's correct? What wires would I swap around using these

https://nextgenguitars.ca/products/mini-switch-standard-dpdt-on-on.html

THRobinson

New member

Bridge may be further away... I think my pickups got lost in transit. Sigh.